HUNTSVILLE, Alabama – Engineers and scientists in the Huntsville area are using next-generation manufacturing techniques and the latest advances in rocket engine technology to build cost-efficient hardware aimed at lifting U.S. ambitions in space and safeguarding security at home.

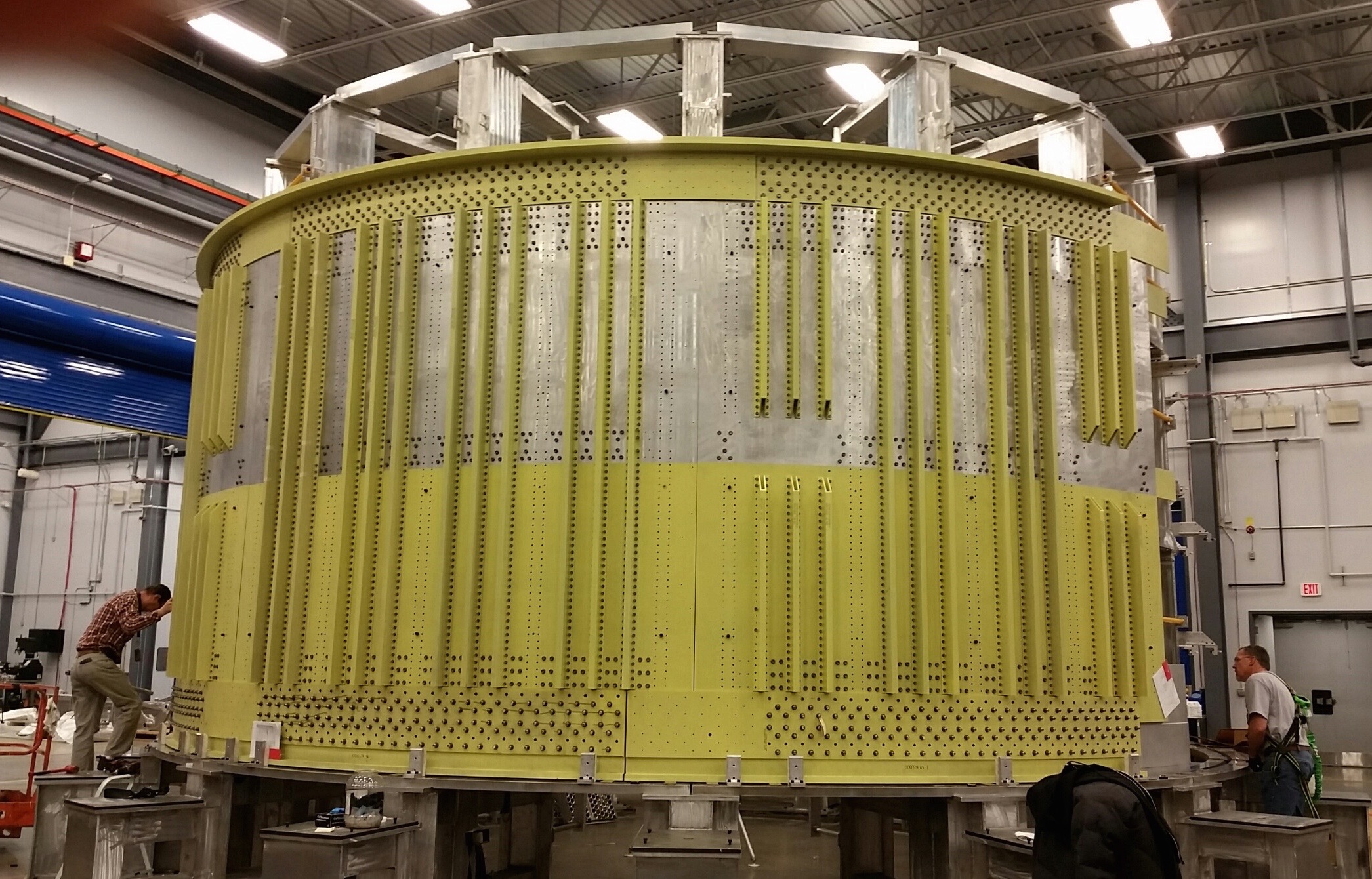

Dynetics, a Huntsville firm with roots dating back 40 years, and partner Aerojet Rocketdyne are leaders in the effort. The team is utilizing 3-D printing and other sophisticated manufacturing methods to produce an updated version of the Space Race’s crown jewel – the powerful F1 rocket engine used in the Apollo program.

NASA awarded Dynetics a contract in 2012 to study whether it was possible to develop an affordable American-made booster engine based on the Saturn V’s proven F1. Since then, NASA has added other work to the contract for the Dynetics team to design, fabricate and test key components of another rocket engine under development, called the AR1.

“Alabama is leading in developing advanced manufacturing techniques in low-cost, affordable, complex space systems, both in rocket engines and the launch vehicles themselves,” said Steve Cook, vice president of corporate development for Dynetics. “That technology is here, and we will continue to utilize it and put it into future programs.”